Effective Resin Chemistries for the Protection of Electronic Component

Epoxy Resin Chemistry

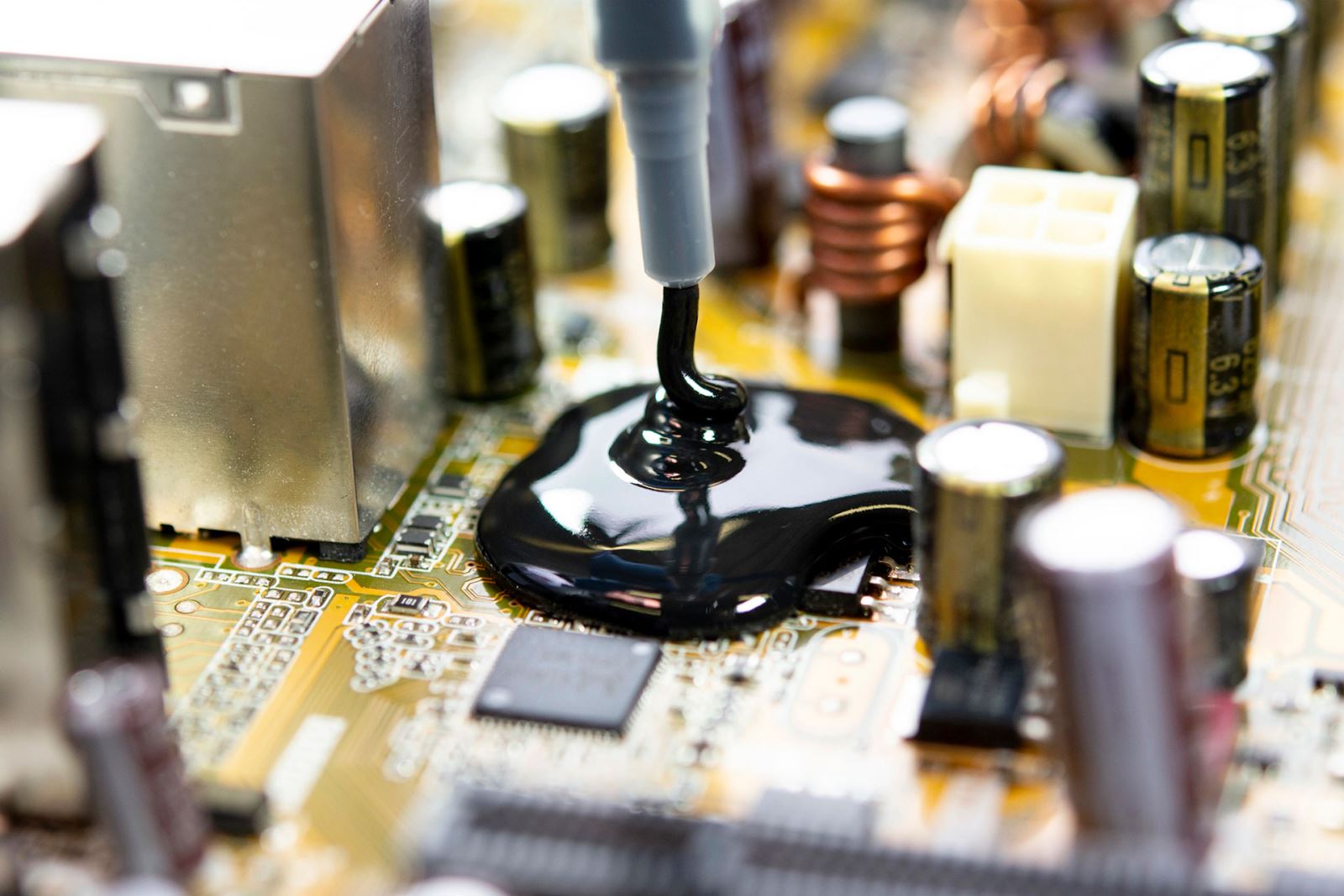

Epoxy resins enjoy wide popularity among electronics industries due to their excellent electrical and mechanical properties, as well as their ability to offer protection against chemicals and high temperatures. Their use enables protection for electrical components against dust, moisture and short circuits, and as standard epoxy resins have better thermal conductivity than air, they provide more efficient dissipation of heat from components, thus prolonging service life.

Today there are a wide range of different epoxy based resin systems available, offering a wide range of different properties. The curing process for epoxy resins is generally slow, but a range of different cure speeds and cured properties can be obtained using amines, amine modified polymers or polyamides as hardeners. However, while the reaction can be very fast, it can also be very exothermic, leading to the possibility of a runaway reaction. This can be mitigated by modifying the hardener chemistry or by using fillers, which will help absorb the heat of reaction and which can be used as a flame retardant. Note here that the temperature at which a resin is cured will affect not only its cure speed, but also the quality of the final cured resin. It is therefore good practice to carry out some trials before committing to a specific cure rate.

The increasing use of electric vehicles has led to a change in the market requirements for many resins, but particularly epoxies. Since e-mobility is a fast changing and evolving market, the various performance criteria required for the components of the vehicles is constantly evolving and improving. Since resins are used in many areas on a vehicle, from sensors and displays to the motors themselves Electrolube is at the forefront of providing solutions to meet the requirements of the automotive electronics industry.

It is almost a given that with each new design generation of components, they reduce in size but will become more powerful. Generally speaking, increased power will equate to more heat being released, hence the drive to develop new resins with improved upper temperature operating ranges, this is relevant for both for continuous and short term operating temperatures. There is also a requirement to increase the thermal conductivity of resins enabling improved heat dissipation from electrical components.

Electrolube’s epoxy resin portfolio includes a variety of clear, white and black, single- and two-part products with a host of useful properties to meet most requirements from potting and sealing to dipping, including exceptional electrical and thermal characteristics, flame retardancy and resistance to chemicals and fuels.

Polyurethane Resin Chemistry

Polyurethane Resin Chemistry in general provides a rigid encapsulation when epoxy resins are cured, while polyurethane resins are elastomeric or rubber in their cured state. This is especially useful if the flowerpot circuit contains sensitive components. Like epoxy resins, polyurethane resins have chemical, dust and moisture resistance, as well as excellent electrical insulation and good adhesion to most substrates, both metal and plastic. Unlike their epoxy counterparts, polyurethanes usually have a lower exotherm during curing, even for faster curing systems. However, it is important to note that in general, cured polyurethane resins should not be allowed to have a continuous service temperature above 130°C.

Polyurethane resins are widely used in a wide range of applications, where their natural elasticity reduces the amount of stress applied to the components compared to epoxies. This means that components with thin or fragile legs can be easily potted. In addition, a number of polyurethane resins are thixotropic. This means that the viscosity is low during mixing, but once poured, the viscosity of the resin increases rapidly. Due to this, it allows the resin to be placed correctly and does not flow through small holes on the PCB.

The exponential increase in the use of LEDs over the past few years has led to them becoming the default lighting choice for most applications. However, LEDs require some protection, depending on the environment to which they are exposed. Optically transparent polyurethane resins have become a very popular choice for protecting LEDs in more demanding environments. These resins have been specially developed with a fully aliphatic polymer backbone to offer the best yellowing resistance due to UV degradation. In many cases, designers are now looking at the use of resins not only to provide a level of protection for the lighting unit, but also to improve aesthetics.

Depending on the choice of resin, LEDs may appear as separate light sources on a solid light bar. As noted earlier, most polyurethane resin 130°C. temperature has a top, but with a careful formulation of this limit maximum temperature to 150°C. It is possible to remove, but still the same flexibility that we can protect and chemical resistance polyurethane would be expected to.

Silicone Resin Chemistry

Polyurethane resins electrolube of white, black, blue, clear, straw, hazy/cloudy and comes in optically clear formulations, as is common with series and epoxy, high temperature exposed to chemical contamination of the environment offers a number of features to meet your needs. These; it is mechanical stress or shock, and the introduction of moisture.

Silicone Resin Chemistry As with some polyurethane resins, optically transparent silicone resins have superior resistance to UV light and have been shown to maintain their clarity through rigorous laboratory exposure test regimens. This well-documented UV resistance is ideal for LED applications where resin color stability is important to ensure the minimum color temperature shift of the LED lighting unit itself.

Although it is not as popular as epoxy and polyurethane resins, silicone resins offer some obvious advantages when used as encapsulation resin. Because the cured products have a high degree of elasticity, excellent chemical, dust and moisture resistance, good electrical insulation properties. Silicone resins tend to be more expensive than epoxies or polyurethanes, but are ideal when high continuous operating temperatures (200°C) are required. In addition, when working with silicon systems, the exothermic temperature is really very low, ensuring compatibility with heat-sensitive components. Unlike epoxy and polyurethane curing mechanisms, complete curing of silicone curing can take from 24 to 48 hours, depending on the depth of the pot or the thickness of the sample and the geometry of the potting unit.

One limitation is that silicones usually require moisture to be present to advance the reaction, so attention should be paid to the curing conditions, especially with regard to moisture. Silicone resins also have excellent adhesion to most substrates, including both metals and plastics. In october to optically clear resins, Electrolube also supplies other pigmented two-part silicon resins for a range of applications. They can have a variety of requirements, ranging from extreme temperature resistance to excellent flexibility and high thermal conductivity. For some industry segments, silicones offer many advantages.

The majority of electrolube resins are two-component systems that react to form polymeric materials when mixed in the right proportion. With careful formulation, the properties of the cured resin can be adapted to meet individual customer requirements.

Permabond

Permabond Demak

Demak Therminol

Therminol Eastman Aviation

Eastman Aviation LEFA

LEFA Naia

Naia LPS

LPS Marlotherm

Marlotherm Atul

Atul LPS Sprays

LPS Sprays

LPS MAX

LPS MAX

DYKEM

DYKEM

Anaerobics

Anaerobics

Cyanoacrylates

Cyanoacrylates

Structural Acrylics

Structural Acrylics

2-Part Epoxies

2-Part Epoxies

1-Part Epoxies

1-Part Epoxies

Polyurethane Adhesives

Polyurethane Adhesives

UV Adhesives

UV Adhesives

Low Temperature

Low Temperature

Mid Temperature

Mid Temperature

High Temperature

High Temperature

Vapour Phase

Vapour Phase

.png)

MRO Products

MRO Products

Turbine Engine Oil

Turbine Engine Oil

Hydraulic Fluids

Hydraulic Fluids

Cleaners

Cleaners

Anti Icing

Anti Icing